Creating good edges is kind of like personal hygiene…

if you do it properly it goes unnoticed.

It’s only when you stop washing that it attracts any attention!

It’s only when you stop washing that it attracts any attention!

Thus, by definition ‘ good’ edges are not noticed – if you do a good job of blending them, then they are not there to be seen.

This post is inspired by a great email I had from someone who emailed asking how one gets great edges on a prosthetic.

I love this kind of question because it is simple, direct but makes me really think about the answer. After much deliberation, my answer to you, Howard, and anyone else who is interested in great edges on prosthetics is in this post!

===============

The point at which a prosthetic appliance stops on the skin creates an unavoidable edge (if it does not then it is not a prosthetic any more, but a mask!) and the ideal situation is to blend that edge to nothing so you can’t see it. That is where 99% of all prosthetic issues occur once the thing is applied.

Getting a flawless blend between the ‘fake’ of the appliance and the ‘real’ of the skin is where most of the work is in prosthetic makeup. This can be hampered by an unintentional thicker edge and a noticeable colour difference between the skin and the appliance after application.

Whether visible edges are important or not depends on what the makeup is for. If the makeup is for a theatre production for example where close scrutiny is not so likely, then less than perfect edges are not so much of an issue. However, most situations require for the best blend possible and that is what we are concentrating on here.

For great edges that need to get close to a camera lens, here are the things that need to happen to get great blending edges on appliances…

-

Start with a good lifecast

Fresh plaster lifecast straight out of the alginate. Despite the mess and slight imperfections, this cast had no distortions!

If making a custom appliance, you need to get off on the right foot, so to speak.

It needs to be an accurate copy of the original, without distortion, major air bubbles or serious imperfections.

Small air bubbles etc can be filled and the seam line can be shaved down. However, large discrepancies are harder to fix and may require a re cast!

-

Make sure your sculpted edge is tapered well.

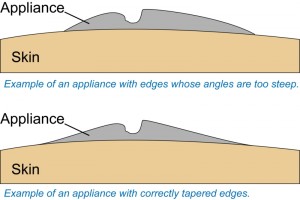

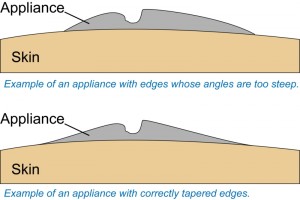

This illustration shows how a rapid or steep angle will be obvious on skin, where as the gentle taper naturally blends into the skin.

Ensure the form of the sculpt shifts naturally to the surrounding anatomy

of the skin surrounding it. Match the texture of the surrounding skin right up to the edge.

The illustration to the left demonstrates how the angle of the appliance approaching the skin must be sculpted to taper naturally.

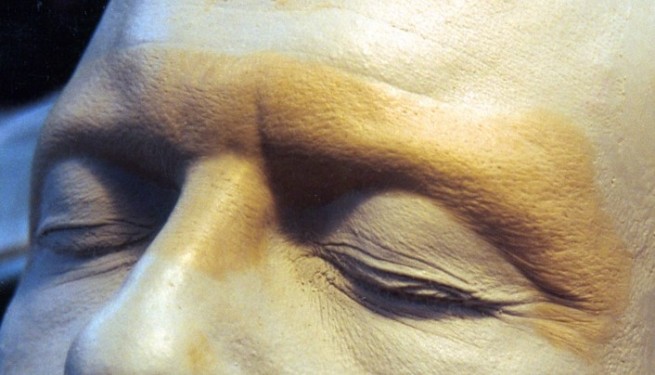

Forehead sculpt for a TV show. This appliance was very thin, and the edges blended nicely into the existing forehead.

-

Decide where to put your edges carefully.

Consider carefully where exactly the edge finishes. For example, if a cheek appliance is made a little larger so that the bottom edge finishes beneath a jawline where it is less noticeable. In fact sometimes you may need to…

Larger scale prosthetic makeups were often broken down into smaller, overlapping appliances. This was a technique developed by Dick Smith to counter the shrinkage that occurred with Foam Latex, the main appliance material of the time.

Nowadays, almost all large scale prosthetics are achieved using silicone which does not shrink – quite the reverse, actually – and consequently larger, single appliances that cover more of the face or even a whole head or body part have come back into use.

This silicone makeup used a large wraparound face appliance with seperate forehead, nose and ear appliances. The appliance around the face could have been made from smaller overlapping pieces, but I wanted to reduce the amound of blending edges.

This technique requires more skill to handle such a large appliance but can cut down application time considerably.

Edges can finish under costume or the back of the neck and there are fewer of them.

Not all situations warrant a huge appliance, so this needs to be weighed up and a balance struck.

A good mould is essential, so that you get an accurate copy of the sculpture in reverse. In the case of a two-part mould with a core and a mould, the two must fit together perfectly, with no warping or distortion of the two parts to fit together. Making sure any location keys work properly and avoiding undercuts is important too.

-

Cast good appliances from your good moulds.

Casting well from your moulds is also important. No good having a great, accurate and durable mould and then not actually getting a usable appliance out of it. Carefully getting the appliance out of the mould (de-moulding) is also an important skill to avoid damaging the edges.

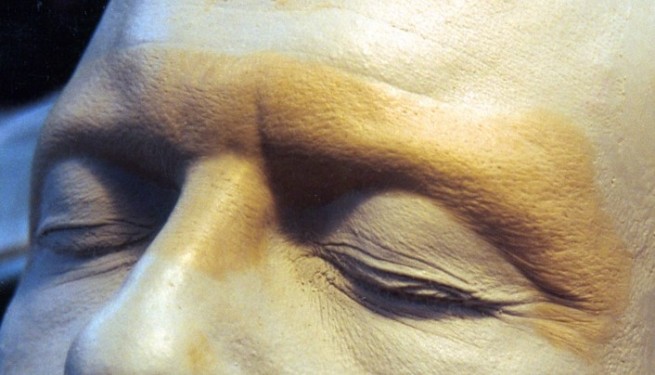

This image shows just how thin a thin edge can be. An appliance with an edge like this is a joy to apply once you know how. Notice how it is all but separated from the excess (or 'flashing') by a cobweb-thin membrane.

Often, an edge known as flashing will still be attached by a thin membrane (see image above – also note how the skin texture and bumps etc go right up to the edge as mentioned above). Preserving this edge until the last possible moment before application will enable you to handle the piece for painting or even application. This will reduce damage to the ‘live’ edge (the actual edge that will finally be applied to the skin and blended) before the piece is needed.

Good application is essential as you can obviously make a bad job of applying a great prosthetic. If the super fine edges necessary for a natural blend should roll under themselves or get stuck badly then it will need to be fixed so the edges are not obvious.

Fine edges by their nature are beautifully thin but also difficult to handle and are easily damaged. I once had a makeup artist complain that the edges were too thin and she could not actually apply them. She was complaining that the edges were too thin which is precisely what you need to get a great blend.

This incidentally is why appliances are rarely reused, as the edges on an otherwise useable appliance become easily damaged during removal. A new set is usually required for each day.

Once the appliance is glued down flawlessly, then the colouring is the next stage. There are a few things that need to be considered when making up appliances that do not happen during conventional makeup.

The way colour grips skin and an appliance may differ, so ‘wiping’ colour on with a sponge is not likely to work. Instead stippling, flicking, airbrushing or dabbing of colour is much better for prosthetics.

Below, you can see two makeups halfway through colouring. The foam latex makeup on the left is much more work as foam is naturally opaque, and much of the work goes into getting a translucent effect. The image on the right is painted only on one side so you can clearly see how the absence of a red stipple on the wolf nose is missing.

These two images show how edges are still clearly visible once applied but before colouring is complete. Image on the left was for David White (Altered States FX) and was for a commercial. The pic on the right was for a reality TV show done for Neill Gorton (Millennium FX).

Also, conventional cosmetics do not work well on appliances as they appear differently on skin that prosthetics, sometimes soaking into the appliance material and not the skin.

This is another way in which edges can be unintentionally revealed so using the right kind of makeup (PAX paints, Rubber Mask Grease Paint or Alcohol Based colours for Silicone etc) will help prevent this issue.

-

Maintain those good edges.

Edges do not remain unchanged throughout a shooting day. Mrs Doubtfire lied to you!

If an actor is sweating all day in action scenes, then edges will start to degrade and need maintenance pretty swiftly. I spend most time on set watching the makeup gradually deteriorate and respond to this by eating cakes, drinking coffee and fixing them with glue on a cotton bud. After meals there is usually a big mess to attend to – especially if someone had a pile of fried chicken for lunch and the mouth appliance is hanging off like a dogs ear in the wind.

Re-gluing, patching holes and fixing any colour which has been damaged is what you will do all day, and hopefully, the result is a makeup which looks the same on camera in every take.

Hi Def is a new issue for prosthetics for TV shows given that traditional TV images and screens were not so large and detailed. For movies the bar was always high as close ups on a cinema screen leave little to hide behind. Consequently, the level of attention to detail and quality given to movie projects now needs to be given to TV also. This means working to a higher standard and maintaining best practice at all times. You were going to do that anyway though, right?

-

Practice screwing it up, then try fixing it.

Doing this well requires the experience gained from practice, and practice remains the most crucial element to being capable in any field of expertise. I seriously recommend slapping something on badly so you can then practice dealing with folded edges etc.

Regardless of what you learn, whatever course or workshop you attend or any book you read or Video you watch…none of the information will be retained or made relevant to you unless you perform the actions repeatedly. Just because you know something does not mean that you can actually do it.

Document everything to ensure this is recorded so you and others – me even – can review your work honestly. Always take photos or video if possible. The images remain the same regardless of your fleeting emotions about how you feel towards them.

Flashing around the edge can be used to preserve the ‘live’ edge you want too use later. This can be used to handle the appliance prior to use, and be pinned etc when pre painting etc.

This image shows a silicone appliance being prepainted. Notice that the flashing extends way beyond the edge and can be used to pin the appliance to a board making it much easier to work with.

Never cut the flashing off with scissors as this creates straight lines which are rarely seen in nature or the human face.

Instead, tear the edges along the thinnest point where it should naturally create a feathered and slightly irregularly shaped edge which is easier to blend into the skin.

Material softness matters, because if the appliance is stiffer than the skin it is applied to, then when the skin moves, the appliance becomes apparent as it cannot move the same way. It is relatively easy to adjust the softness of silicone in a consistent manner but foam latex requires more experience with mixing ‘rise’ time.

Confused? Foam is strange animal that confuses even the experienced – it can even sense your fear!

You can fill edges with a filler sometimes known as bondo or cab-o-patch. It is made by mixing togther Pros Aide with Cab-o-Sil (Fumed Silica* – an inert filler used in many resins and other casting materials to bulk it out and thicken).

This material is then carefully applied to the areas which need to be filled, and dries clear and plexible, working with the makeup (usually foam latex or gelatine).

For silicone appliance makeups, you can also use a silicone paste such as Sculptgel or a thickened mixture of the silicone used to make the original appliances for the best colour match.

This is a last resort as it also can create a border of smooth, texture free skin which is just as noticeable as a step or thicker edge – in an ideal world you shouldn’t need it, but hey…whatever works!

*You should be able to get hold of this wherever you buy casting resins and materials. Always read and understand the health & safety material and ensure you have adequate protection when using materials.

Creating prosthetics involves a series of procedures – each one building on the last – and each one provides fresh opportunity to damage what has been does so far. Treat each stage with the presence of mind it deserves, and you have done all you can to get the best edge.

================================================

Well, there you go. That is what happens when I get emailed a great question that sets my mind thinking. Thanks Howard – that was about a week of spare time but it’s my own fault…I can’t resist!

I had a blast putting this together. If you have any technical questions that I might be able to shed 2275 words on, please pop a comment below and email me at mail@learnprostheticmakeup.

Seriously, I’d love to know if this was any use to you and what you think.

-Stuart

All material, images and text © Stuart Bray 2011

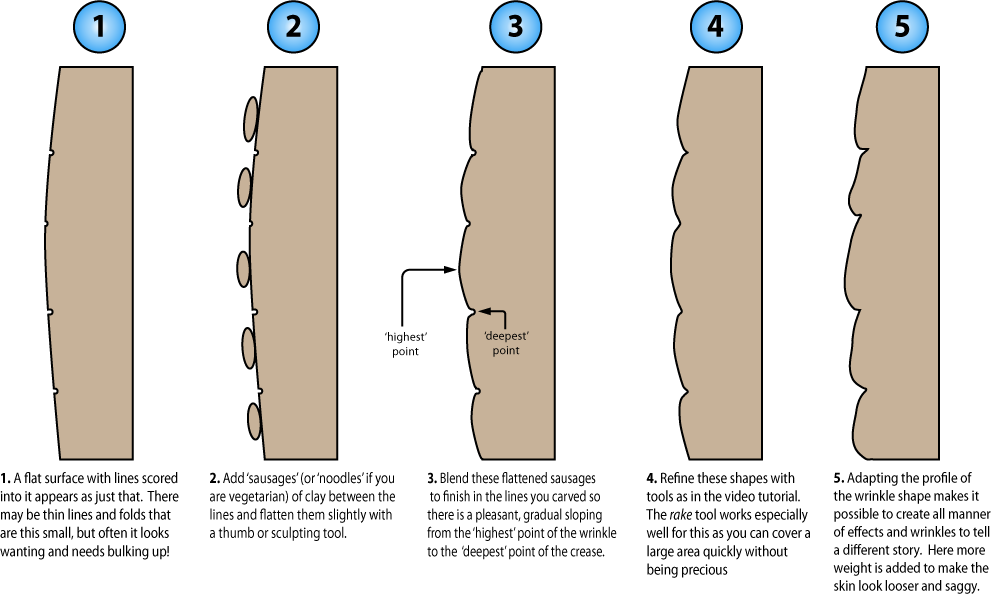

This post takes a look at creating wrinkles and breaks down a straightforward method which takes the mystery out of how to make them much more realistic every time.

This post takes a look at creating wrinkles and breaks down a straightforward method which takes the mystery out of how to make them much more realistic every time.