Blood ! Podcast #15!

It’s something gets thrown around a lot in film, TV and theatre. There’s bad blood, good blood, mudbloods, blood thicker than water and blood brothers.

This episode we’re talking about blood, and our guest this time is Rob Smith, blood master as well as an all-around effects bod. He also runs a lot of foam, and makes exquisite soft foam appliances which you really need to feel to appreciate.

He makes his own pieces but runs a lot of foam for other people, and you’ll certainly have seen his work if you’ve been to the cinema in the last few years!

Blood needs to be a number of things:

- The right colour

- The right opacity

- The right viscosity

It also needs to be:

- Safe to use (skin, mouth and costume)

- Easy to clean up

As a product, there are lots of different kinds of things which can be classified as blood. For example, blood as a real biological product does things – like clot, dry, separate, form scabs and flake once dry.

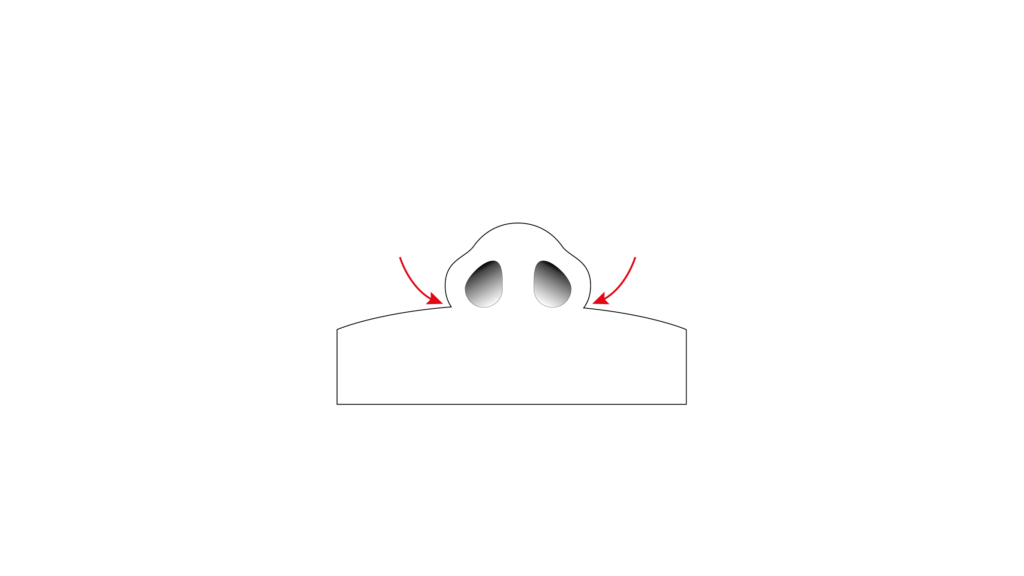

One of these blood drops is real!

An artificial blood won’t do that, so to create all these different possibilities, there are blood effects products like the standard liquid, flowable blood that comes directly out from an opening in the skin to ‘clotted’ blood, scab, wound fillers and pastes.

Often these are made from the same sugar or corn syrup base, thinned with water or thickened and then coloured with food grade pigments to an appropriate shade. However, as convenient and mouth safe as that may be, it attracts flies especially when shooting in warm climates. Sugarless bloods, drying bloods which are alcohol based and even specialist bloods for use in eyes and mouth are available for use where appropriate.

All this means, of course, a large amount of product range, which we touch on a bit with Rob, who makes a lot of blood, but focusses mainly on the flowable blood which gets used in rigs to pump and splash around on set.

Blood Gags

I’ve done a fair few blood gags (a lot of necks, weirdly), that is makeup effects which use blood that gets pumped on cue, and thinning blood so it flows right under pressure means a fair bit of effort and testing to ensure it looks right.

The thing about a blood gag is figuring out what kind of tubing to use and where to put it – we could do a whole podcast just on the ins and outs of blood gags – but there’s all that stuff under the piece which needs to be right, and then the appliance over the top is just to hide that plumbing job underneath.

If blood is too thin and translucent then it doesn’t look right, and if it is too thick then it won’t move and spray correctly. The fact it needs to travel under pressure, through various different tubes and connectors etc. All that changes the way the blood flows, so knowing this and doing lots of tests to make sure you have a good idea about how that particular gag is going to work is important.

Interview with Rob Smith

Anyhow, listen to some bloody wisdom from Rob Smith, which we recorded in his home.

Anyhow, listen to some bloody wisdom from Rob Smith, which we recorded in his home.

It’s worth pointing out the guitar you’re going to hear is Rob, plucking away just for fun as he showed me his guitar collection hanging from the walls in the lounge.

Pretty cool stuff.

We chatted for a long while so I’ve split this up into two hour-long chats, and we shall release part 2 within the week.

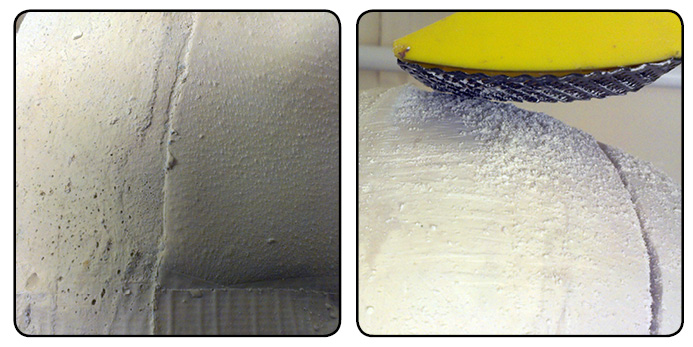

Rob makes a great blood for use on silicone appliances which flows and smears realistically and which doesn’t ‘bead’ up on oily surfaces which can happen with many water and syrup based blood. You can see which is which in this comparison!

Teaching & Learning Makeup FX

Being in Belfast this week teaching at Titanic Creative Management made me reflect on the various kinds of learning environments I see so I talk a bit about some of the issues I see in colleges, namely that the institutes often fail the tutors. They squeeze the goodwill and best efforts of many tutors and some don’t even appreciate the requirements of a course leaving tutors woefully unsupported. I think many of the tutors do a good job despite their faculty rather than because of it.

I have said before that makeup is often underestimated, people may attend a makeup course because they themselves wear makeup so…how hard can it be, right?

The majority of people I’ve met at colleges really do care about being there, and some are outstanding. However, I’ve been to other places which felt like it was a crèche for big 20-year-old kids and you know that shit wouldn’t truck if they were an apprentice.

I care about the craft side of things and I don’t want to see people wasting their time. When college attendance is ruled by ‘do you have the money’ rather than ‘look, this is hard work…do you really want to do this?’

College makeup school tutors, I salute you.

There are people who just won’t turn up on time and who skip entire weeks, suddenly to return at the last minute as assessments rear their head. Then that poor tutor has to give up endless extra hours to mend that as best they can because the college took on someone that frankly doesn’t want to be there. If that was a freelance apprenticeship, I can just fire you for being shit.

If you’ve paid to be there, it shifts the power so the relationship between the learner and the teacher is transactional rather than one of mutual reliance. Read that original blog post here: http://www.learnmakeupeffects.com/what-is-the-best-way-to-learn-makeup-effects/

There is of course nothing wrong to pay to learn, I myself pay to learn things and am glad I can do so. However, the people taking the money at colleges and universities are not directly responsible for dealing with the learners on a day to day basis. Private makeup schools, however, usually have a closer relationship with their attendees, and as such, I have seen a marked difference in attitude – they are there for a short time and really want to be there. I suppose also college is the first logical step after school, so many are attending fresh from a school education and are younger. I know I did!

This is what goes through my head when I get asked three times a week which college is best etc. or whether they should go private. It seems a college will provide an academic qualification, and that is the appeal to do that over a private course.

However, If a large portion of the course is endless theory which is not required on a set, you can become ‘qualified’ whilst being utterly useless. If you pump out thousands of students like that, that serves nobody except the facility which charged you a small fortune for the privilege.

Will Digital Kill The Practical?

Lots of people ask this question, and the changes are new relatively speaking so a thorough understanding of the future effect of it is not something any one person has a full explanation for. The truth is it isn’t going away, it isn’t taking over everything and it isn’t something that you can’t take part in.

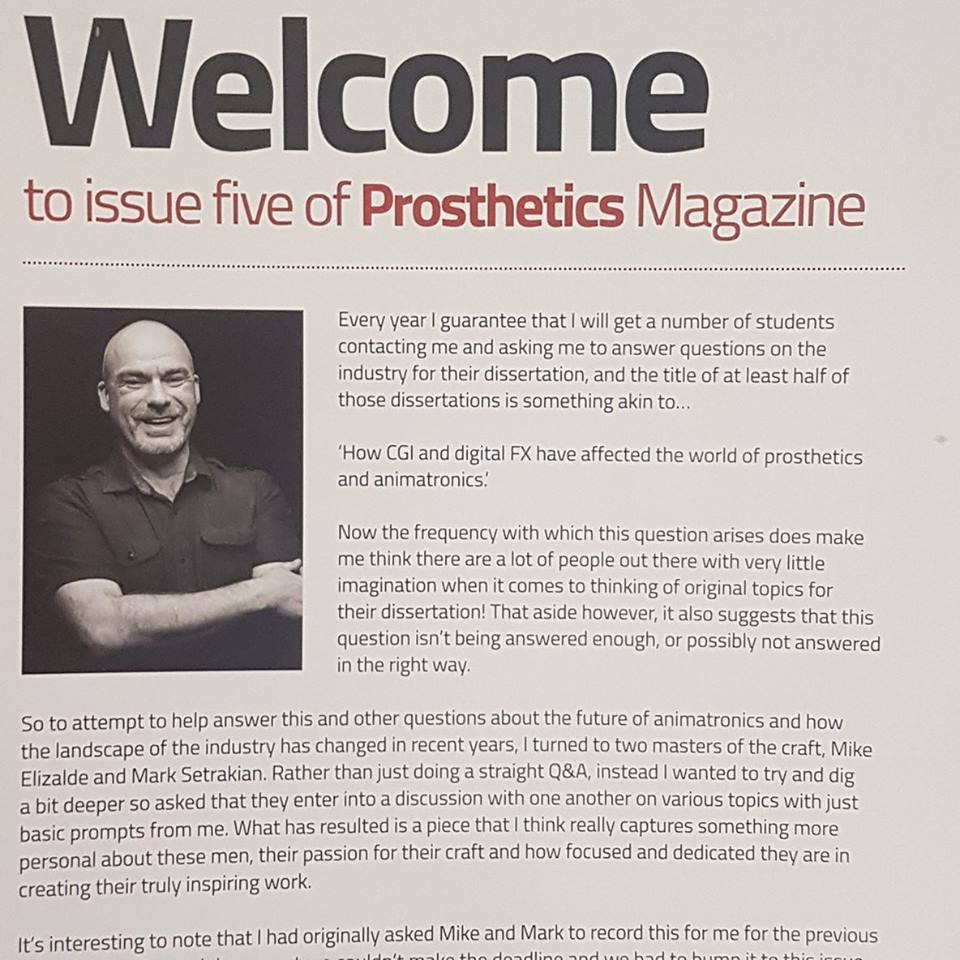

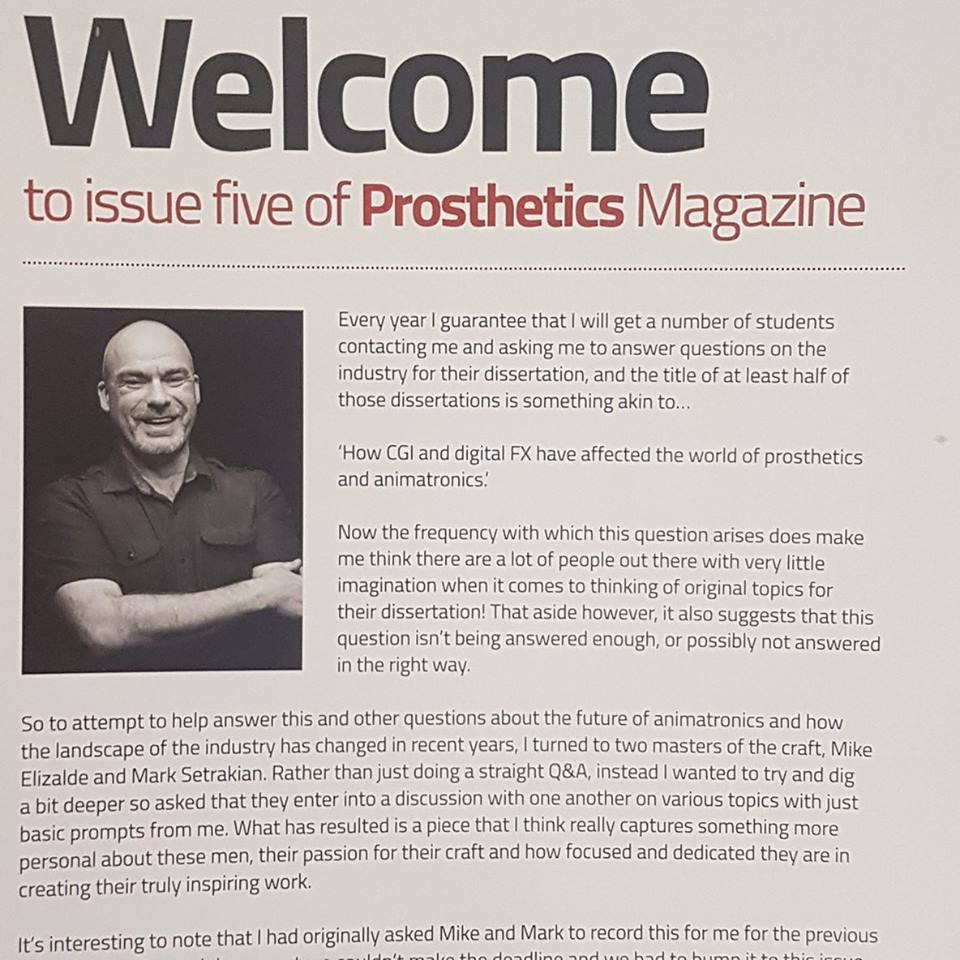

Lots of people are getting in touch and asking for survey responses, so it’s clearly a hot topic. It even made it to the editorial of the latest Prosthetics Magazine (well worth it by the way, I’d recommend it. Get yours here in print and digital: https://www.prostheticsmagazine.co.uk/ )

Transferable skills needed in both digital and practical work remain good basic abilities: good design, ability to render and understand anatomy, and using reference to constantly upgrade what you know. The computer doesn’t do it all for you – there is a skilled person behind the keyboard. You could be one of them.

There are a lot of areas which come under the digital umbrella, and the trick is to find a way in if you are interested. If you like sculpting then check out the digital sculpting programs and photo retouching is usually done in Photoshop. This is a paid for programme but you can still get CS2, an old version for free here: https://www.adobe.com/support/downloads/detail.jsp?ftpID=3466

Also check out the free image editing software from GIMP: https://www.gimp.org/

Digital Sculpting

Digital sculpting is changing a lot of things slowly, and programmes like Zbrush and Mudbox make it possible to apply the same editing qualities of a Word document to a sculpture. Clay is great and I recommend using it – you don’t need to choose just digital or just clay, I think using both is important. However, for no money at all, you can introduce yourself to the digital sculpting

To check out and download Sculptris: http://www.learnmakeupeffects.com/what-is-the-best-way-to-learn-makeup-effects/

The stripped down version of ZBrush is called Zbrush Core, so check that out here: http://store.pixologic.com/ZBrushCore/.

Keep on trucking! Remember you can get in touch through email on stuartandtodd@gmail.com, through our Facebook Page: https://www.facebook.com/stuartandtodd/ or comment on the blog post, http://www.learnmakeupeffects.com/rob_smith_pt1/

Rob Smith continues his chat with me about foam latex, blood and other FX related goodies.

Rob Smith continues his chat with me about foam latex, blood and other FX related goodies.

Anyhow, listen to some bloody wisdom from Rob Smith, which we recorded in his home.

Anyhow, listen to some bloody wisdom from Rob Smith, which we recorded in his home.

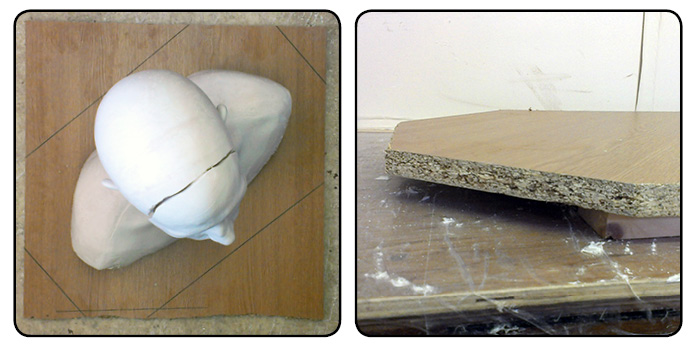

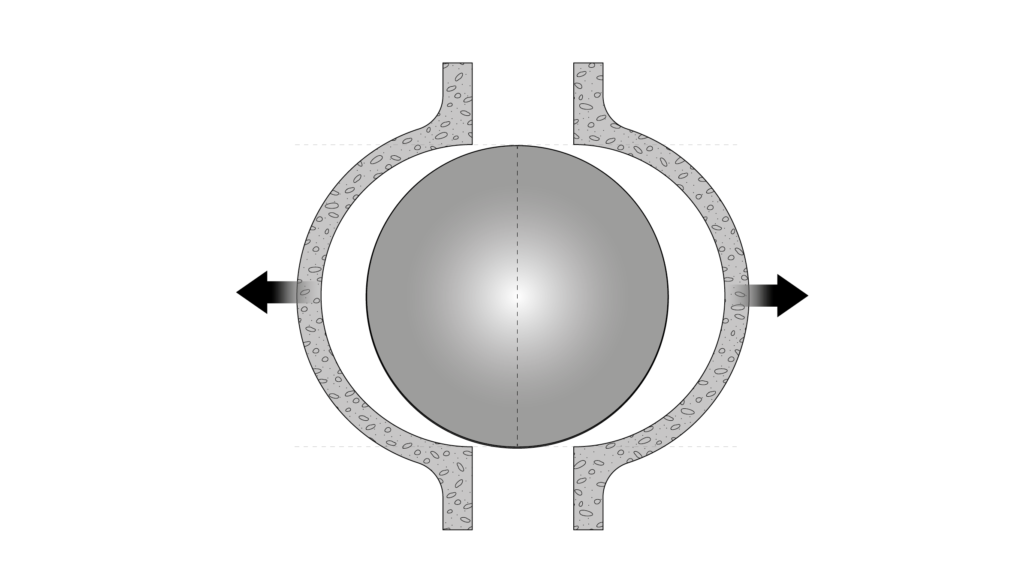

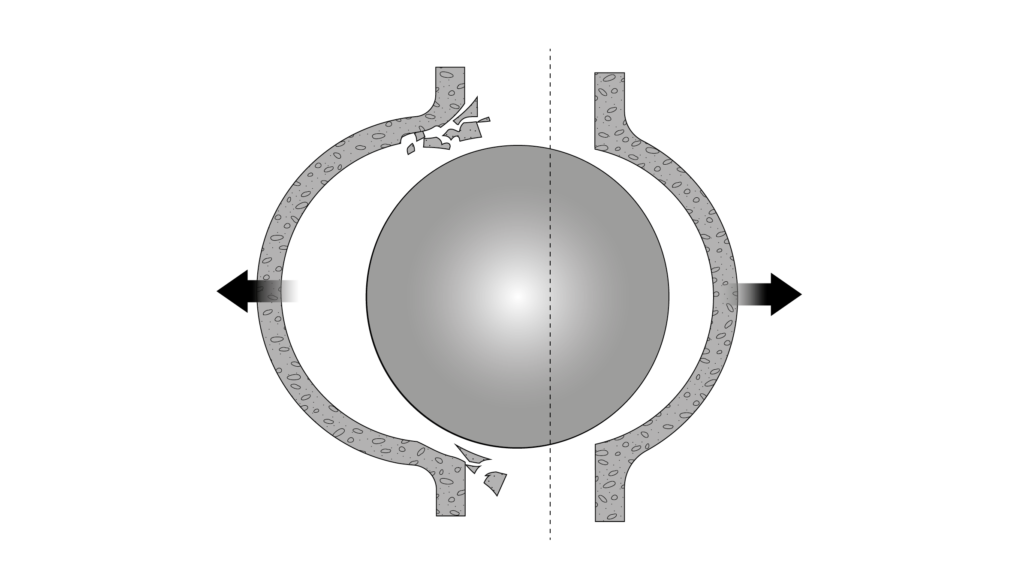

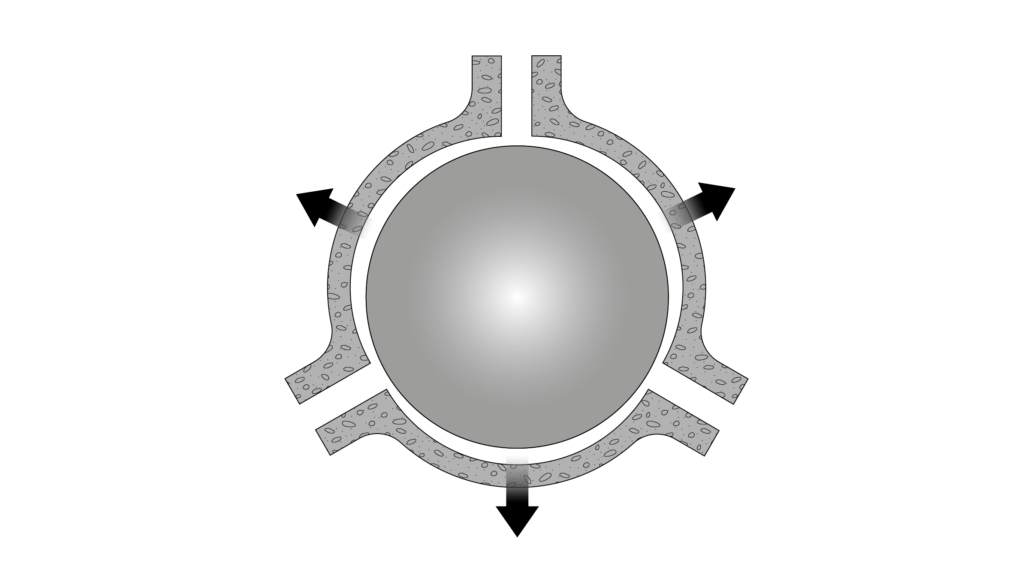

One of the biggest tales among mould making folklore is the curse of undercuts visited upon unfortunate souls who failed to spot them.

One of the biggest tales among mould making folklore is the curse of undercuts visited upon unfortunate souls who failed to spot them.

Brick In The Yard isn’t the most obvious name to give to a successful FX material supplier.

Brick In The Yard isn’t the most obvious name to give to a successful FX material supplier.

Rob Burman is a damned nice fella and kindly took some time to share some of his wisdom, and we are all grateful he did. Thanks, Rob!

Rob Burman is a damned nice fella and kindly took some time to share some of his wisdom, and we are all grateful he did. Thanks, Rob!

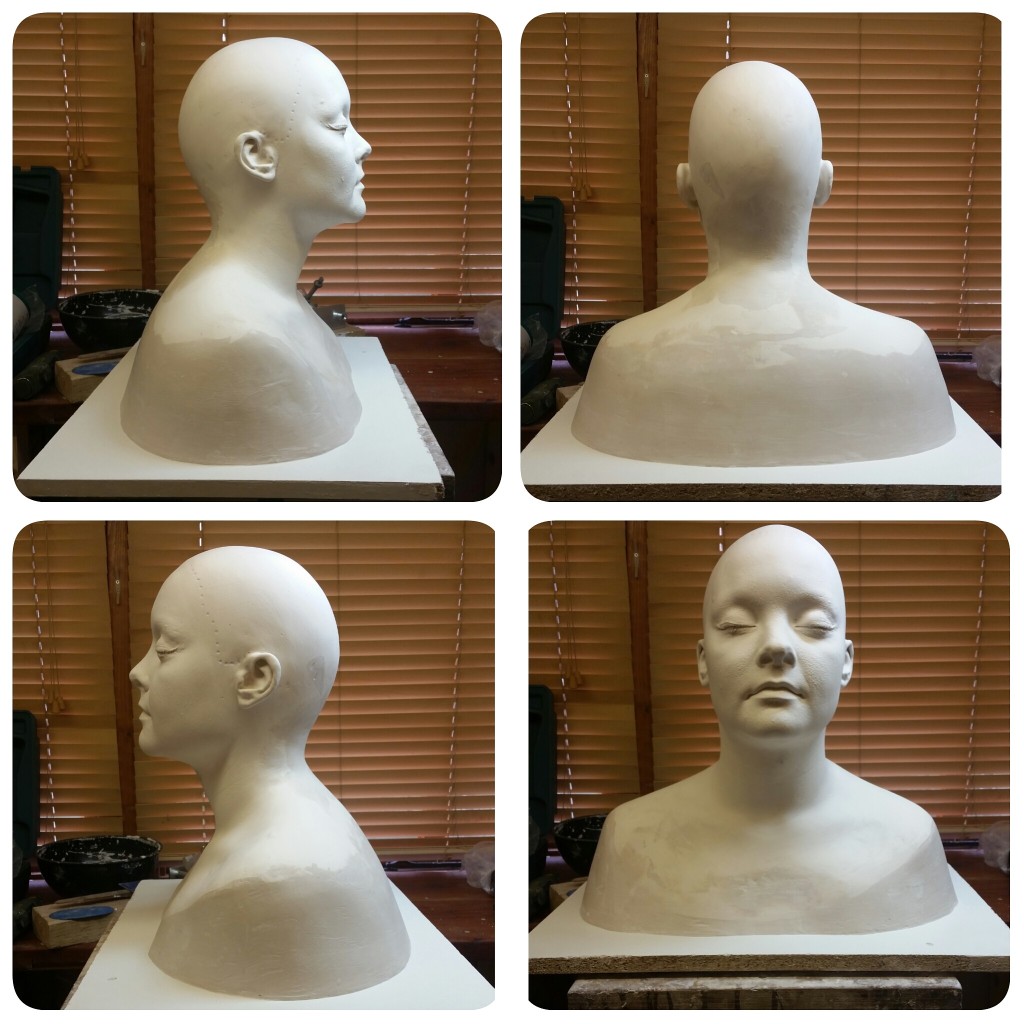

The last time we talked about making foam latex, the craft and materials involved in actually producing the foam. This time around, we figured it would be a good call to look at painting and art finishing.

The last time we talked about making foam latex, the craft and materials involved in actually producing the foam. This time around, we figured it would be a good call to look at painting and art finishing.

Essentially, cap plastic was always sold as a liquid and this made it a ‘hazardous’ item as far as air freight was concerned should the container leak. It was never an issue for us in the UK where we had things sent by road, but air freight made it a different issue.

Essentially, cap plastic was always sold as a liquid and this made it a ‘hazardous’ item as far as air freight was concerned should the container leak. It was never an issue for us in the UK where we had things sent by road, but air freight made it a different issue.